With the New Year upon us, it’s a good time to take stock and prepare for this year’s activites and operational maintenance requirements. Its at times like these that decisions are made to move forward with projects to implement replacement systems, and/or ‘clear out’ unwanted infrastructure parts. One resolution we can all embrace is to ensure that a responsible Reverse Logistics process is followed.

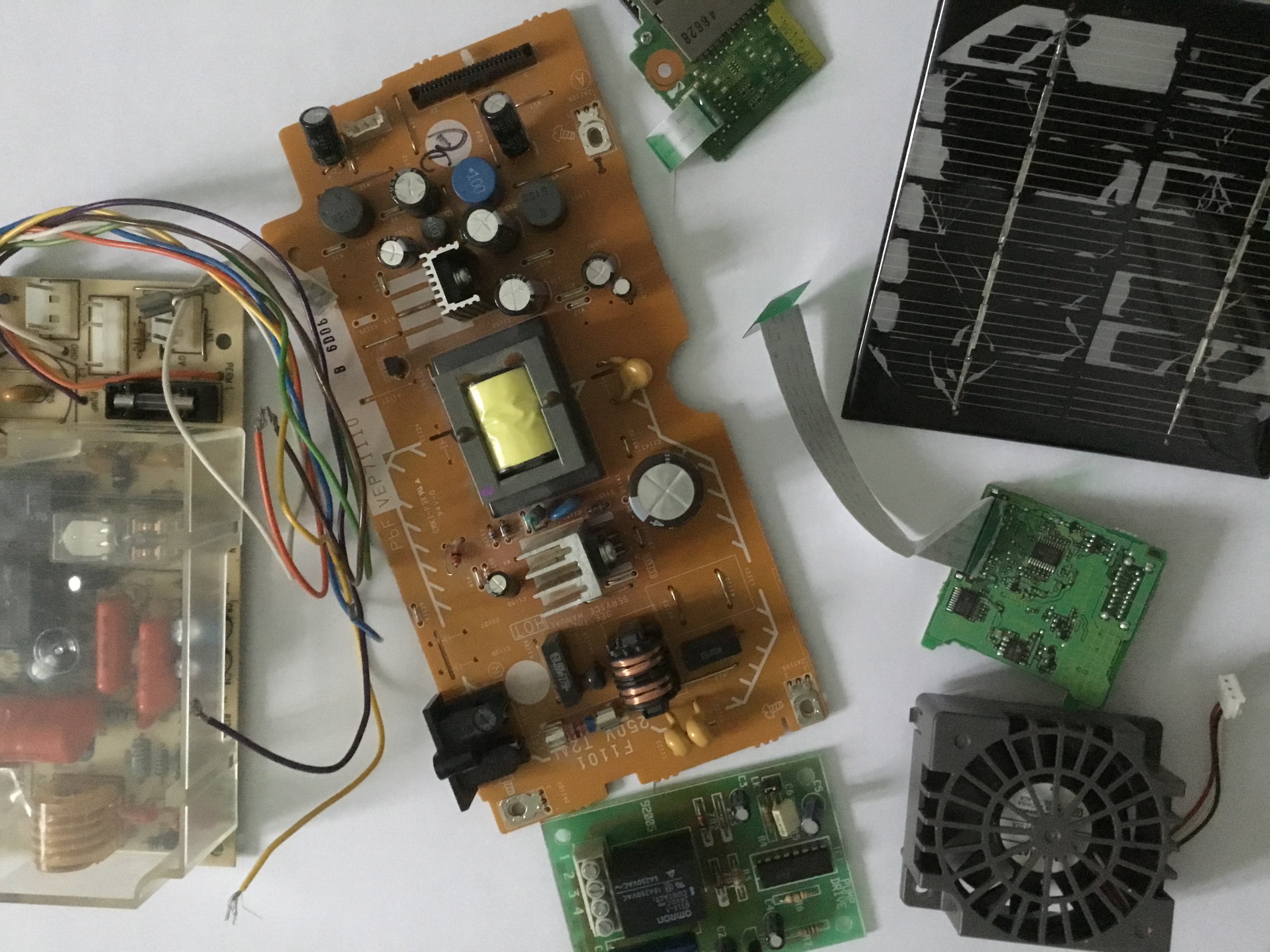

Furthermore, it’s not always the case than there has to be a significant cost to disposal; unwanted infrastructure items in many cases can result in a generation of funds to Customers, either through resale of working spare parts or by recycling of components. This ‘Value Recovery’ can help to pay for replacement systems, as well as disposing of unwanted parts with the least environmental impact.

YellowsBest helps Customers perform their Reverse Logistics whilst achieving ‘Value Recovery’ by taking delivery of systems and parts, cataloguing the items, then providing a managed approach to the resale of spares, maximising the revenue arising. During this no-cost process, whilst the assets have been removed from the Customers’ premises saving storage space, they remain the Customers’ property and can be called back should unexpected spares requirements occur. Anything not saleable is then broken down for recycling, with useful materials extracted which can generate additional funds, and unwanted items disposed of in accordance with WEEE regulations.

We look forward to hearing from you; please get in touch to see how YellowsBest can assist with Reverse Logistics and maximise ‘Value Recovery’ for your organisation.